「UTSURI」.

Cooking Ritual — An exploring New Forms and Materials for a Fillet Knife.

UTSURI

Fish Fillet Knife · Designed · Nov 2025

Made of High-carbon steel, Magnolia wood, Food contact clear resin

-

Fillet knife is specifically designed for the delicate task of processing fish. The blade is typically 6–11 inches long, is thin and flexible to follow the natural contours of fish bones and joints. The blade is made from high-carbon stainless steel so that it can resist corrosion from water and fish. The blade angle is mostly between 12–17 degrees, allows for precise cutting. The handle design prioritizes grip comfort to ensure better control during fine cutting. Due to the demands of kitchen work, the knife handle must also ensure a stable grip for the user even in wet conditions.

-

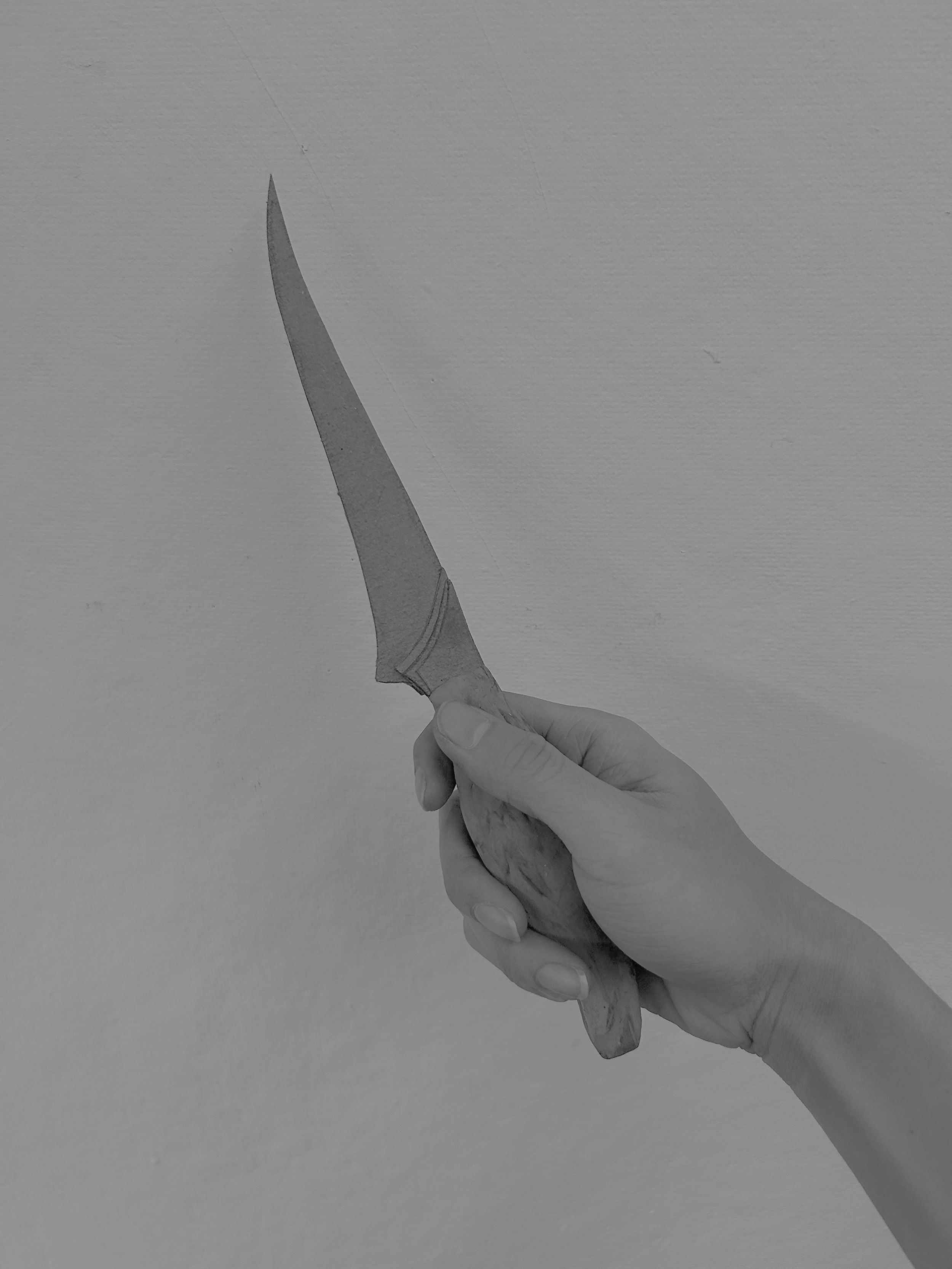

The correct way to hold a fillet knife is to place thumb and index finger on the two sides (It could be upper and lower part or left and right, depends on vertical or horizontal cutting) of the handle near the blade, allowing maximum control of the knife. During cutting, use your thumb to guide the blade while the other fingers stabilize the handle.

After using a fillet knife, it should be hand-washed with warm water and mild dish soap, especially around the joint between the blade and the handle, where fish residue often accumulates. Before storing, thoroughly dry the fillet knife with an absorbent towel to prevent rusting.

-

How to ensure a comfortable handle grip (even in wet conditions)

How to make front side of handle fits securely for a firm grip, while allowing the remaining part of the handle to adapt to both a tight hold and a looser, more flexible grip.

-

UTSURI transforms ergonomic hand-fitting forms into a handle part, providing secure grip and adaptable holding positions. A micro-matte clear resin encases the wooden handle to prevent slipping while enhancing its visual form.

Manufacturing Process

Clay and cardboard prototypes were quickly developed to evaluate hand fit, comfort, and handle-to-blade proportions. The internal wooden handle was then digitally modeled and CNC-cut. The blade was formed through cutting, heating, and repeated forging of high-carbon steel, and refined by grinding and sharpening to precise dimensions and optimal sharpness.